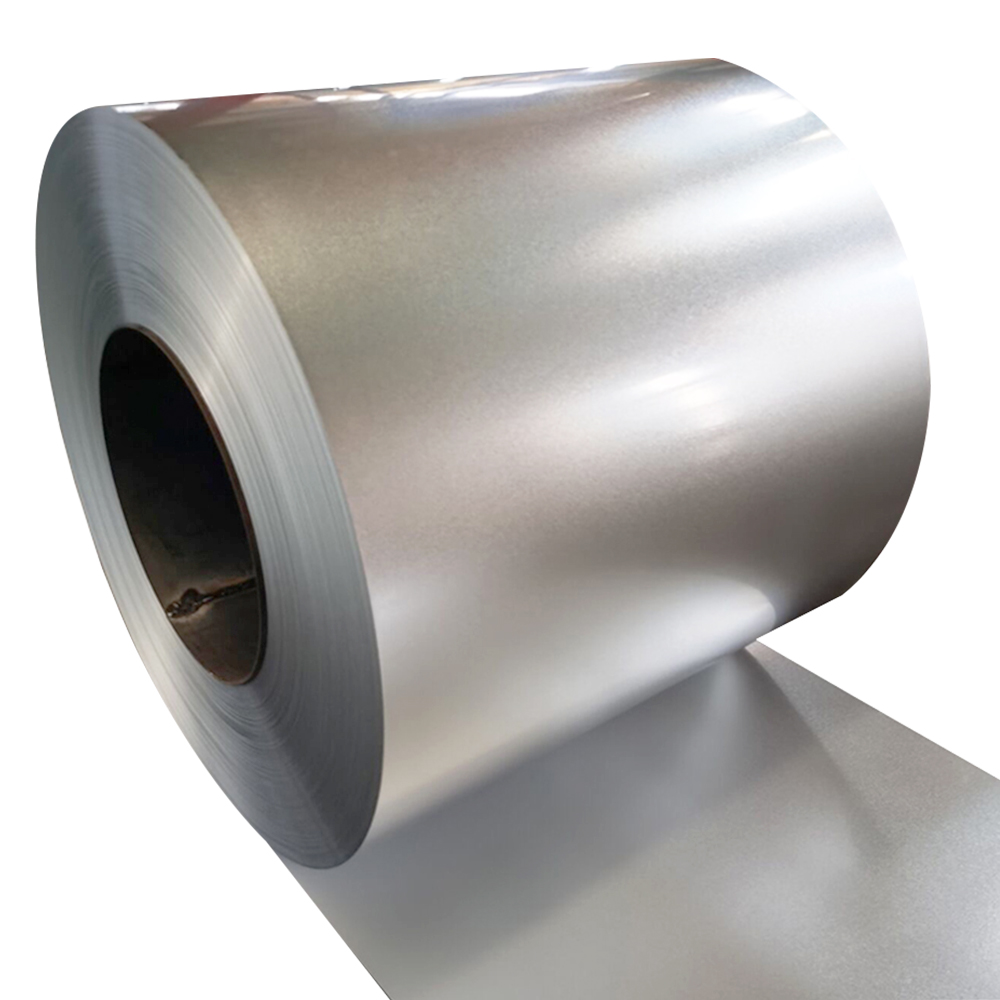

OEM Customized Hot Rolled Steel Coil Manufacturer - Anti Finger Print Galvalume Steel Coils Zinc-zluminum Coated Coil – Win Road Detail:

Galvalume Steel Coil also named Aluzinc Steel Coil /Zinc-alum Steel Coil. The base material is non-alloy low carbon cold rolled steel coil. The surface composition is 55% aluminium, 43.4% and 1.6% silicon cured at 600℃.Galvalume has a gorgeous silver-white surface.

| Thickness | 0.12mm-3mm, according to customer’s requirement |

| Width | 750mm-1250mm, according to customer’s requirement |

| Standard | GBT2518-2008, ASTM A653,JIS G3302,EN 10142, and etc |

| Material Grade | DX51D,SGCC,G300,G550,SGCH570 |

| AZ Coating | AZ30-AZ275g |

| Surface Treatment | Passivation or Chromated, Skin Pass,Oil or Unoiled,or Antifinger print |

| Spangle | Normal(non-skinpassed) / Skinpassed / Regular / Minimized |

| Coil weight | 3-6 tons or as customer’s requirement |

| Coil inner Diameter | 508/610mm or as per your request |

| Hardness | Soft hard (HRB60), Mediun hard (HRB60-85), Full hard (HRB85-95) |

Product Advantages

1.Available for customized specification on customers’ request.

2.Perfect Corrosion Resistance. The service life of galvalume is 3-6times as long as that of galvanized surface.

3.Perfect Processing Performance. Fully meet the requirement of roll processing, stamping, bending, ect.

4.Perfect Light Refelectivity. The ability of reflecting light and heat is twice that of galvanizing.

5.Perfect Heat Resistance. Galvalume products can be used at 315 degree Celsius for a long time without discoloration.

6.Excellent adhesion between the paint. Easy to paint and can be painted without pretreatment and weathering.

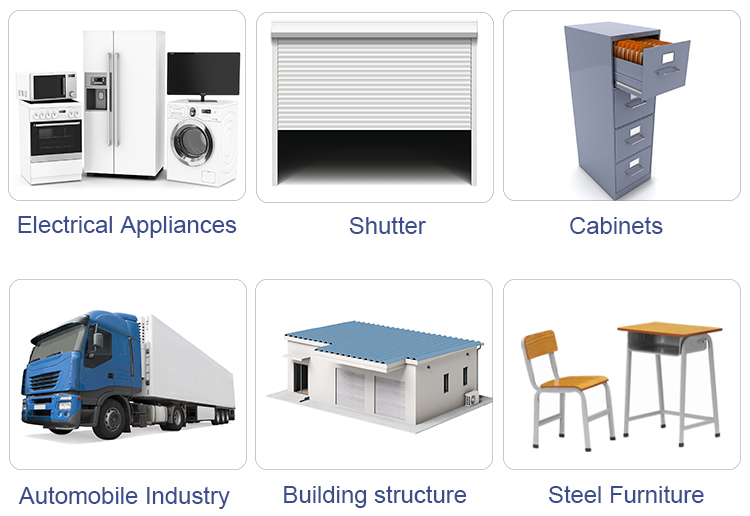

Application

The galvalume steel coil is widely used on Construction, Steel Structure, Household Appliances, Transportation, Steel Structure, Roofing Sheet, Curtain Door.

Packing

1.Simple Package:Anti-water paper+steel strips.

2.Standard exporting package: Anti-water paper + plastic+galvanized sheet wrapper + strapped with three steel strips.

3.Excellent package: Anti-water paper + plastic film+galvanized sheet wrapper + strapped with three strapping strips+fixed on wooden pallets.

Loading:

1.By container

2.By bulk shipment.

Production process

Product detail pictures:

Related Product Guide:

We always follow the principle "Quality Very first, Prestige Supreme". We have been fully committed to delivering our customers with competitively priced high-quality products and solutions, prompt delivery and experienced services for OEM Customized Hot Rolled Steel Coil Manufacturer - Anti Finger Print Galvalume Steel Coils Zinc-zluminum Coated Coil – Win Road, The product will supply to all over the world, such as: Porto, San Francisco, Lesotho, Being guided by customer demands, aiming at improving the efficiency and quality of customer service, we constantly improve products and provide more comprehensive services. We sincerely welcome friends to negotiate business and start cooperation with us. We hope to join hands with friends in different industries to create a brilliant future.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.