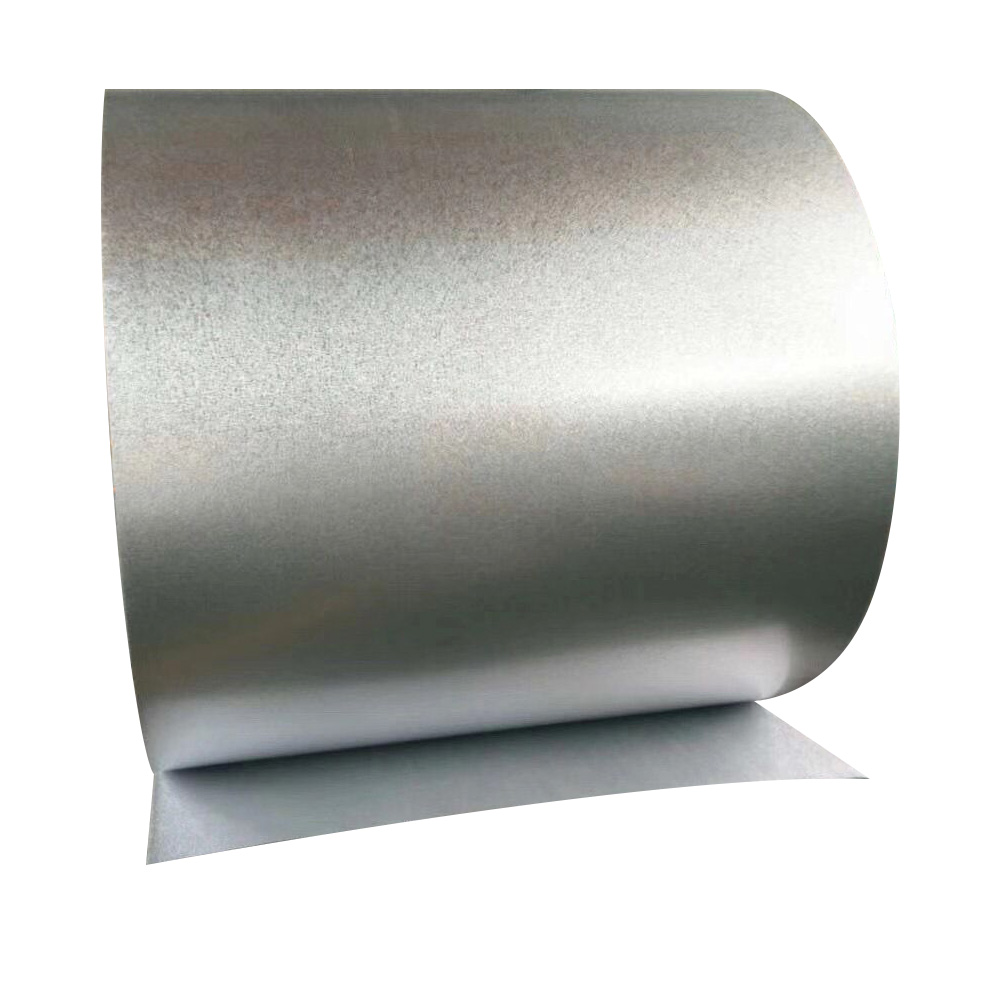

Galvalume Steel Coil also named Aluzinc Steel Coil /Zinc-alum Steel Coil. The base material is non-alloy low carbon cold rolled steel coil. The surface composition is 55% aluminium, 43.4% and 1.6% silicon cured at 600℃.Galvalume has a gorgeous silver-white surface.

| Thickness | 0.12mm-3mm, according to customer's requirement |

| Width | 750mm-1250mm, according to customer's requirement |

| Standard | GBT2518-2008, ASTM A653,JIS G3302,EN 10142, and etc |

| Material Grade | DX51D,SGCC,G300,G550,SGCH570 |

| AZ Coating | AZ30-AZ275g |

| Surface Treatment | Passivation or Chromated, Skin Pass,Oil or Unoiled,or Antifinger print |

| Spangle | Normal(non-skinpassed) / Skinpassed / Regular / Minimized |

| Coil weight | 3-6 tons or as customer's requirement |

| Coil inner Diameter | 508/610mm or as per your request |

| Hardness | Soft hard (HRB60), Mediun hard (HRB60-85), Full hard (HRB85-95) |

Product Advantages

1.Available for customized specification on customers' request.

2.Perfect Corrosion Resistance. The service life of galvalume is 3-6times as long as that of galvanized surface.

3.Perfect Processing Performance. Fully meet the requirement of roll processing, stamping, bending, ect.

4.Perfect Light Refelectivity. The ability of reflecting light and heat is twice that of galvanizing.

5.Perfect Heat Resistance. Galvalume products can be used at 315 degree Celsius for a long time without discoloration.

6.Excellent adhesion between the paint. Easy to paint and can be painted without pretreatment and weathering.

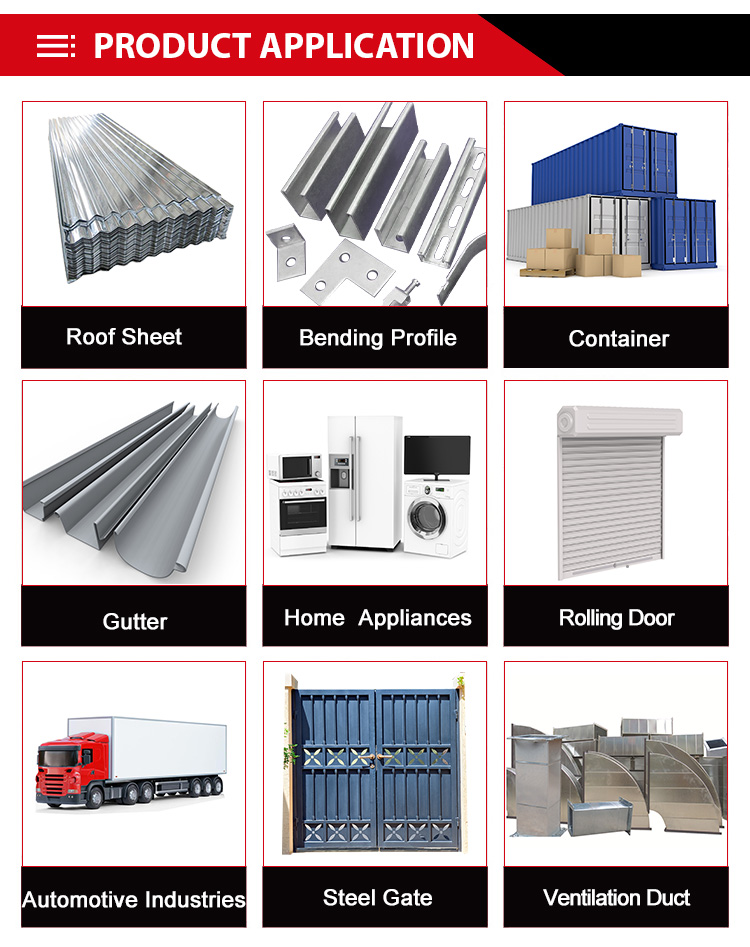

Application

Galvalume steel coil has a wide range of applications, such as roof panels, wall panels, light steel keels, heating radiators, car bodies, fuel tanks, cable armored steel tapes, plastic greenhouses, granaries, shipping containers, household appliances and appliances, ovens, explosion-proof steel belts, outer covers of air conditioning and ventilation systems, solar water heaters, packaging boxes for chemical products, and color plate substrates, welded pipes, steel windows, cold-formed steel materials in the metallurgical industry, etc., have a very broad application prospect.

-

Galvalume Coil / Precio De Bobinas Galvalume / ...

-

Coil Galvalume G550 Manufacturer 0.35mm 0.43mm ...

-

High Quality ASTM A792 G550 Aluzinc Coated Az 1...

-

ASTM A792 AZ60 AZ150 Galvalume 1220*1.1mm,1.25m...

-

Bobinas de aluzinc/ galvalume steel coils AZ150...

-

China Factory Price Aluzinc Galvalume Metal Coi...