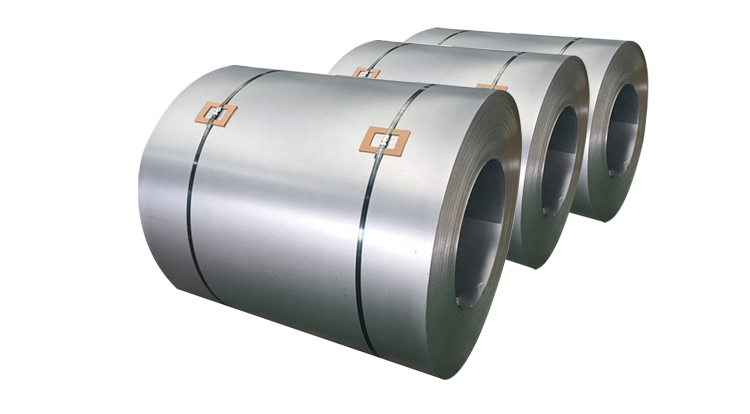

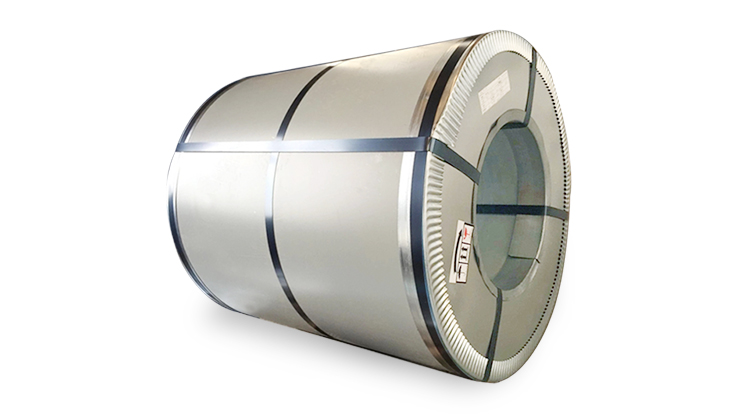

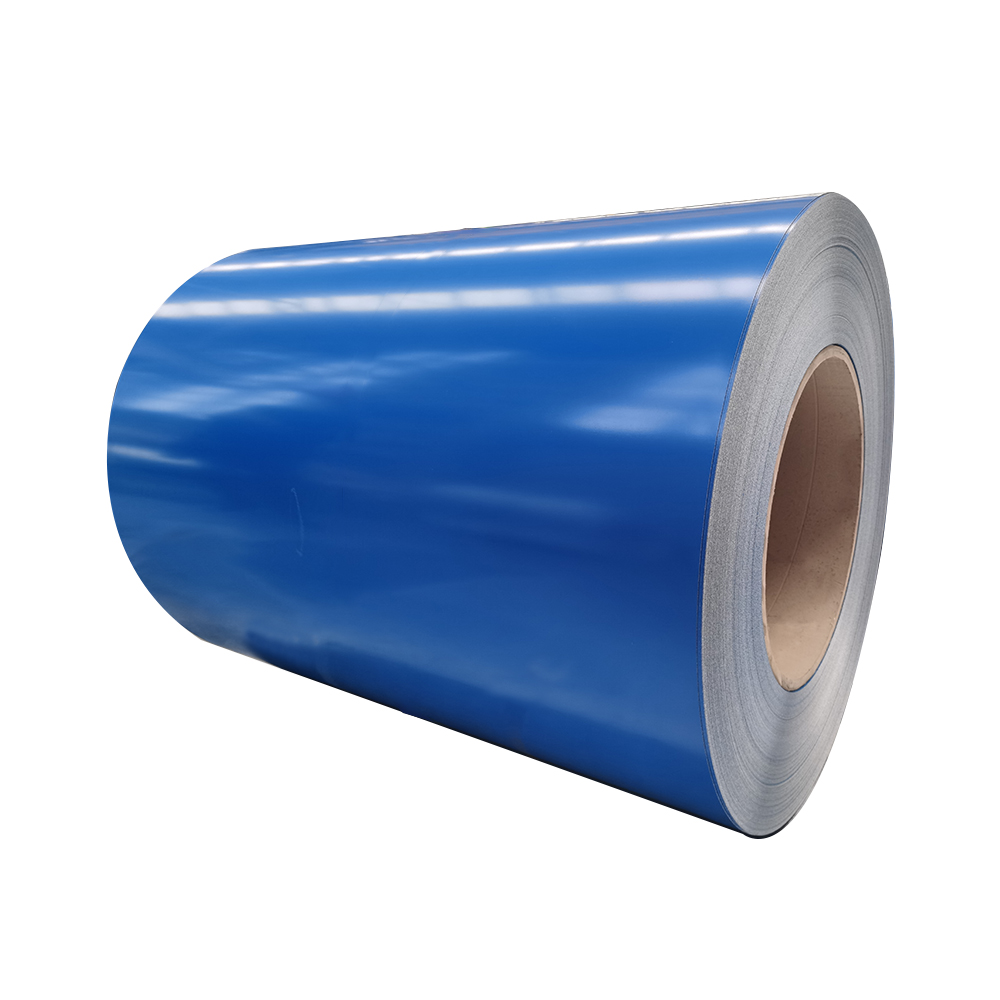

Zinc-Aluminum-Magnesium steel coil (zn-mg-al plate)

Due to the compound effect of these additional elements, the corrosion inhibition effect is further improved. In addition, it has excellent processing performance under severe conditions (drawing, stamping, bending, paint welding, etc.), the coating has high hardness and excellent damage resistance. Compared with ordinary galvanized and aluminum-zinc-plated products, the amount of plating is less but it can achieve better corrosion resistance. Due to this super corrosion resistance, it can be used in some areas instead of stainless steel or aluminum. . The anti-corrosion and self-healing effect of the cut end face is a major feature of the product.

| Base steel thickness | 0.13mm-6mm |

| Coating composition | 1. Zn, 11% aluminum, 3% magnesium, a trace amount of silicon2. Zn, 3% aluminium, 1.5% magnesium), a trace amount of silicon |

| ZAM coating thickness | AZM80, AZM100, AZM150 |

| Steel Grade | DX51D+AZM, NSDCC |

| Width | 600-1500mm (1000mm/1220mm/1300mm/1500) |

| Customized service | customized processing service, customized fabrication by drawingscutting, bending,stampingcut to size according to customers’ demands |

Advantage of Mg-Al-Zn Coating:

1. Longer service life than other coated products.

2.Cut edge rust protection – the hallmark feature .

3. Thinner coating yet more protection – ecologically friendly.

4. Excellent in severe environments – especially coastal and agricultural.

5. Eliminates the need for post dip (batch) galvanizing.

6. Superior forming ability due to coating characteristics Cost savings through longer service life and reduced maintenance.

7. Bridges the product gap between heavily coated galvanized and costly stainless steel.

Packing: Standard exporting package: Anti-water paper + plastic+galvanized sheet wrapper + strapped with three steel strips.

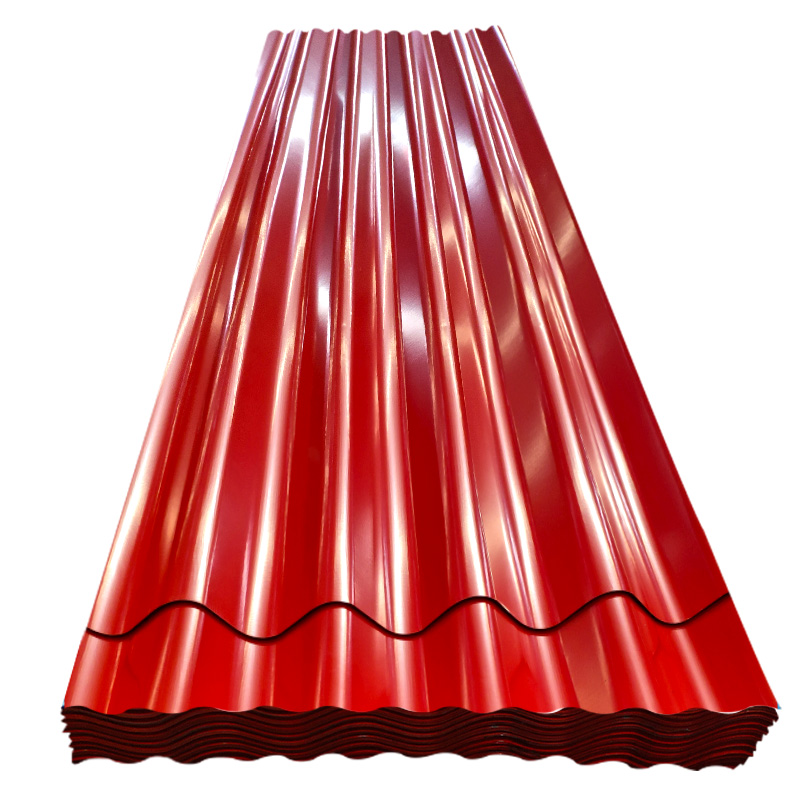

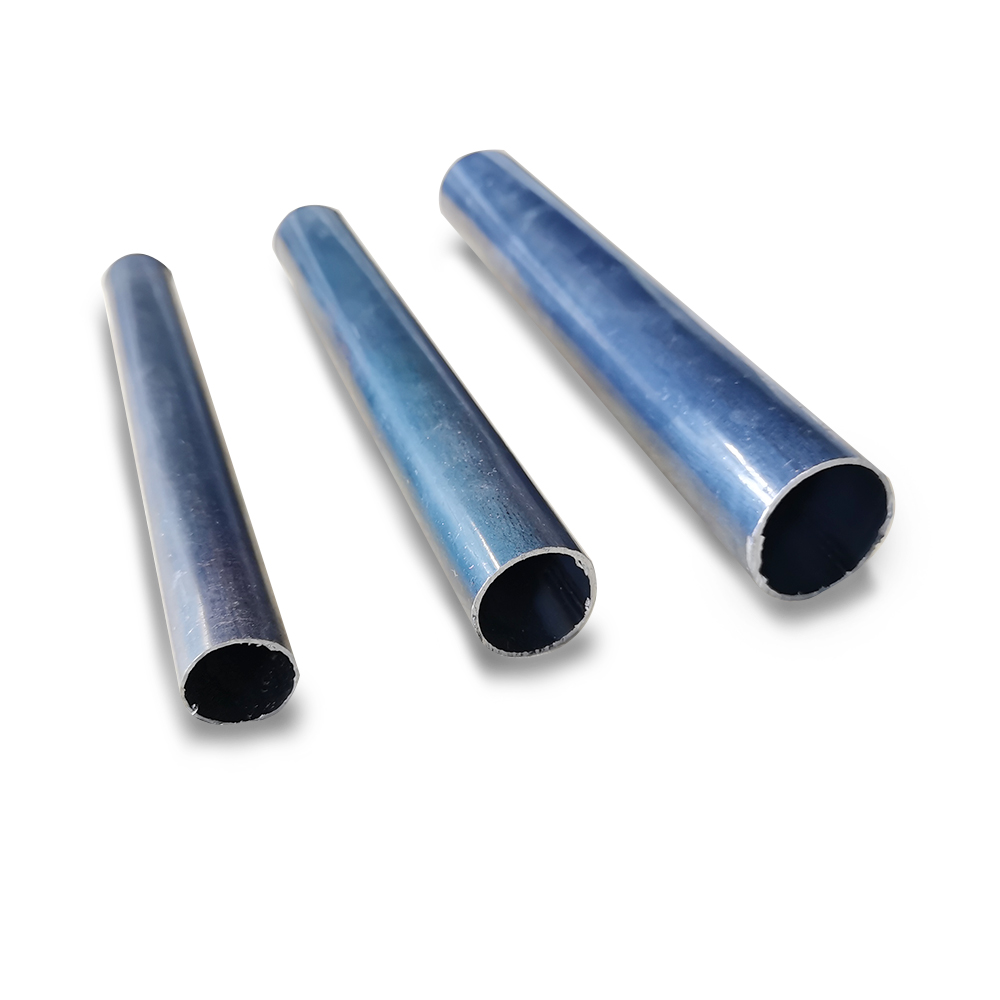

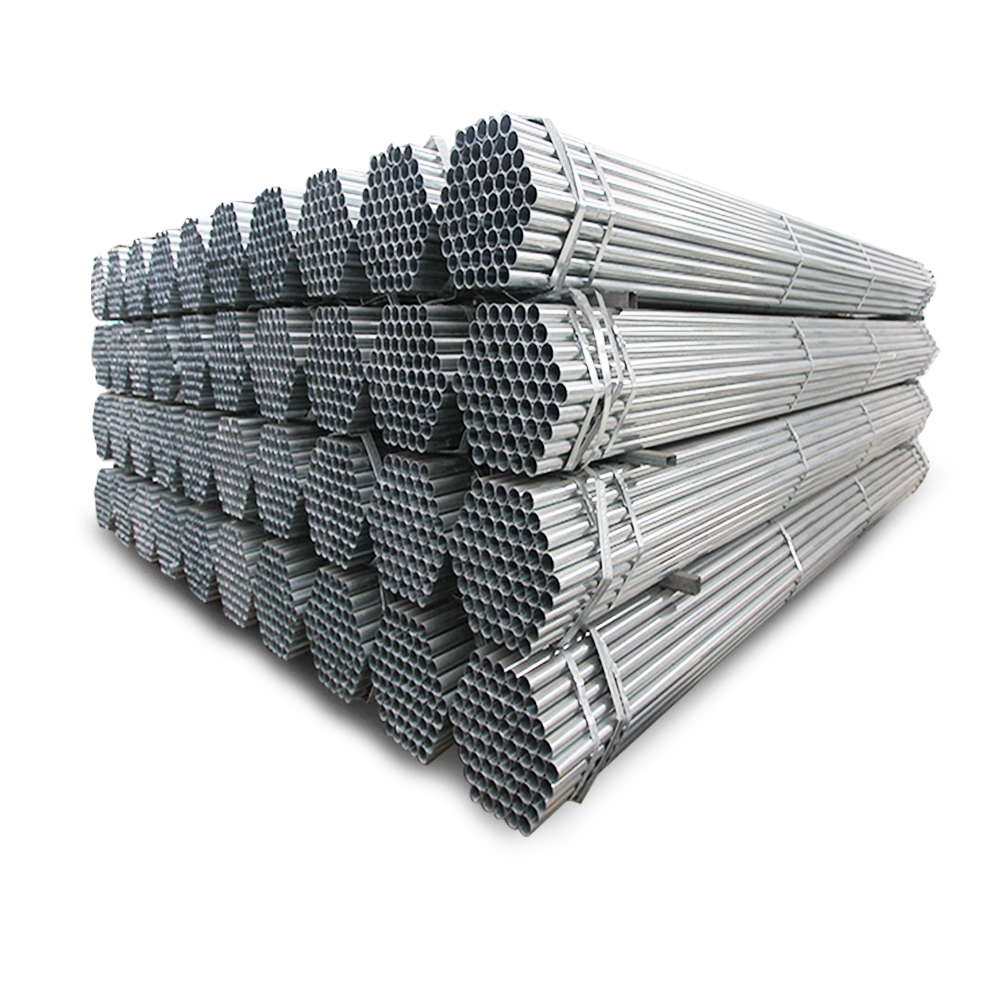

Application:

Suitable applications include: construction (architectural building panels, perforated panels, metal facades, roofing), automotive, agricultural applications (chicken grow out houses, swine containment, hoop buildings, grain bins, silos, etc.), green house structures, industrial HVAC, cooling towers, solar racking, school bus decking, swimming pool, sign posts, guardrail facades, coastal environments, cable trays, switch boxes, steel decking and framing, sound/wind/snow barriers and many other applications. The product is widely used.